Wrapping the battery cell plays a role of protection and fixation

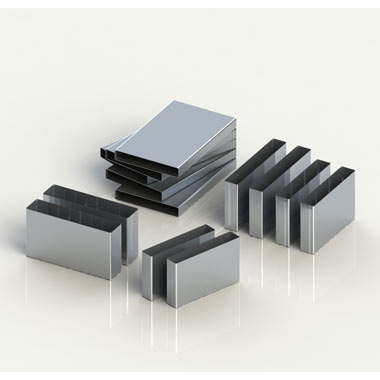

Square battery aluminum shell, a large integrated part with high precision requirements, the surface oxide layer without volatile metals, no metal pollution, no toxicity. Compared with other metal materials, its density is small and light.Adopt multi-station automatic integral molding, the one-time pass rate of processing is more than 99.5%, to ensure the accuracy of products.

The cover plate assembly is a kind of power battery cover with high temperature resistance, high insulation, high sealing and good safety performance. Including lithium batteries with cylindrical and square shell (LFP, LTO, NCM, etc.)

The soft strip used for the connection between electric cores and modules is welded by polymer diffusion welding, which ensures the uniformity of products and improves the production efficiency.

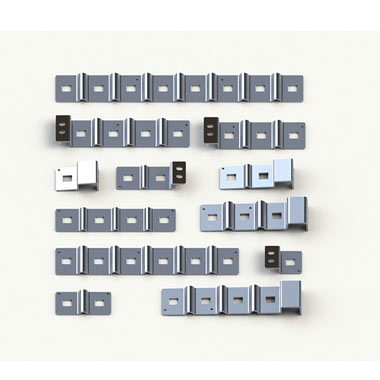

It is used for connecting battery modules, playing a role of electricity conduction and shock protection, which can greatly improve the life and safety performance of power system.